When your compressor needs replacement, you have some options: have your compressor rebuilt or reconditioned, buy a new compressor, or you can choose a remanufactured unit.

While rebuilt and remanufactured compressors look the same, they are very different. It is important to understand the differences and distinct characteristics of the rebuilt solution before deciding.

The air conditioning and refrigeration compressor components in rebuilt units are cleaned and repaired. When a part is too worn and beyond repair, that component is replaced with the same part taken from another used compressor. Consequently, you cannot be sure that the salvaged components in a rebuilt compressor unit are in perfect condition. If the part is worn, this can result in increased friction between moving components. This can result in increased friction causing excessive wear and tear. Over time the unit will fail.

By contrast, remanufactured units are totally remanufactured to conform to the standards of a brand-new unit. Apart from cleaning and replacing worn parts with new, a remanufactured compressor unit can be enhanced for better durability, energy efficiency, performance. This means that all the mechanical tolerances are raised to the most recent OEM standards. The remanufacturing process demands a complete tear down of every returned compressor.

There is a big difference between rebuilt or reconditioned compressors and remanufactured products. Because rebuilt compressors can consist of used components possible uneven wear and ultimately premature failure can result.

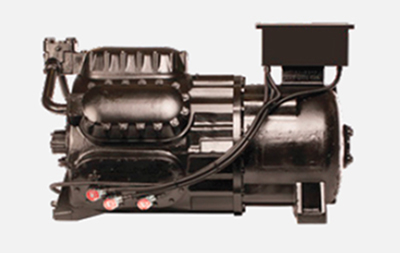

Chicago Compressor & Specialty Products offers high-quality remanufactured compressors including semi-hermetic twin screw compressors and semi-hermetic reciprocating compressors. Both are tested to be the best before we put our name on it.

To find out more about our remanufacturing process or to learn more about our products, contact us.