Compressors come in various sizes, voltages, and capacities and are offered as rebuilt, remanufactured, or OEM (original equipment manufacturer). Between reciprocating compressors, to semi-hermetic compressors, to scroll, screw, single-stage, multi-stage and others, there are many options on the market.

Having a good understanding regarding the types of compressors and how to know what you need for your particular industry is crucial for making a wise choice. In the following article, we will dive deeper into this subject to provide you with the knowledge and resources to make an informed decision. Additionally, using the right compressors for the job will save time and money, providing you with the best end results.

TYPES OF COMPRESSORS

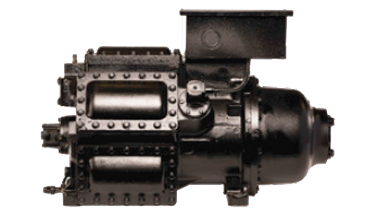

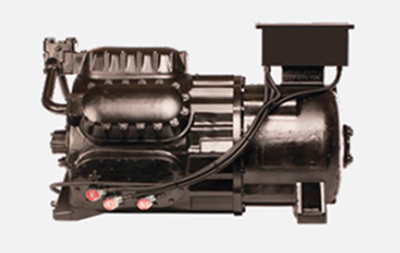

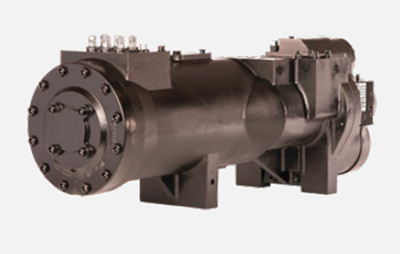

There are two main types of compressors, those that use positive displacement and those that use dynamic compression. Positive displacement compressors include reciprocating and rotary compressors which include screw and scroll compressors. Dynamic compressors include centrifugal and axial sub-categories. Reciprocating compressors are known to provide the most energy-efficient operations.

Chicago Compressor & Specialty Products provides standard-setting remanufactured compression options, including remanufactured semi-hermetic compressors, remanufactured semi-hermetic reciprocating screw compressors, remanufactured semi-hermetic twin screw compressors, remanufactured York compressors, remanufactured York reciprocating compressors, and reciprocating compressors. Additionally, we do offer our customers new semi-hermetic twin screw compressors as well as York compressor rebuild equipment.

CHOOSING A COMPRESSOR FOR YOUR INDUSTRY NEEDS

Now that you have a background on the types of compressors, you may be wondering how you go about choosing one from all of the options in the market. In order to narrow down your search, it is important to consider what you are using it for and what industry you are in. You will also want to think about the amount of horsepower and PSI that may be required. Let’s take a closer look at some of the common compressors used in a few industries:

- Home use or small workshops: Single-stage air compressors work well for most home and workshop projects, such as nailing, sawing, and drilling.

- Auto repair shops: Two-stage compressors are commonly used in the auto industry. Stop by a mechanic shop or drive-through oil change location and you’re sure to hear the compressors in use.

- Construction: Many construction companies will use a mix of single-stage and two-stage compressors depending on the size and power needs of the job. Towable and portable air compressors power various pneumatic tools and offer reliable power and output at many larger construction sites.

- Manufacturing & assembly plants: For most manufacturers and assembly plants, rotary screw air compressors help perform a multitude of tasks. These compressors are heavy-duty and suited for continuous operation in industrial plants and manufacturing facilities.

- Oil and gas: Rotary and reciprocating compressors can be found at many oil and gas industry sites, such as pipelines and processing plants. As a matter of fact, petroleum gas is processed and compressed before it is transported in a pipeline.

- Mechanical contracting: Mechanical contractors work daily with plumbing, heating, cooling and other building systems and utilize industrial air and gas compressors to get many jobs completed. This can include both reciprocating and rotary screw compressors depending on the power needs and other factors involved.

As you see, compressors help many jobs and tasks get completed easier and faster. Choosing the right tool or the job will make your operations more efficient.

DIFFERENCES BETWEEN REBUILT AND REMANUFACTURED COMPRESSORS

When it comes to compressors, rebuilt, or reconditioned units are commonly used. Often using used components from other similar models, these compressors are put back together to create a working unit. The internal parts are cleaned up, repaired, and/or rebuilt to working mechanical form. However, this type of procedure does not come without drawbacks. For one, rebuilt compressors often experience uneven wear and tear as a result of the hodge podge of parts that are used to make them. As a result, this often leads to equipment failure, costing additional money and headaches.

Remanufactured compressors, on the other hand, is a much more thorough process. These units are cleaned up and old components are completely replaced with new parts. By doing so, the compressor is brought back to like new OEM standards and tolerances and will not experience the uneven wear and tear that rebuilt compressors often do. Additionally, remanufactured compressors can receive upgraded parts and technology during this process. Because of this, better performance and energy efficiency may be achieved.

Now that you have a better understanding of compressors, be sure to contact Chicago Compressor & Specialty Products for your upcoming needs. With almost 40 years of experience, we have the team to answer your questions and right fit compressors to your particular needs!